What is "Fiber Optics"?

Fiber

optics refers to the technology of transmitting light down thin strands

of highly transparent material, usually glass but sometimes plastic.

Fiber optics is used in communications, lighting, medicing, optical

inspections and to make sensors. The FOA is primarily interested in

communications fiber optics, so this book will focus on that

application.

Fiber optic communications began during the 1970s in R&D labs around the world (Corning, Bell Labs, ITT UK, etc.) and was first installed commercially in Dorset, England by STC and Chicago, IL, USA in 1976 by AT&T. By the early 1980s, the first fiber optic telecommunications networks connected the major cities on each coast of the USA and began being installed throughout the world.

By the mid-80s, with the introduction of the first singlemode fibers, fiber’s bandwidth and distance capabilities made it significantly less expensive than other communications media and it began replacing all the telco copper, microwave and satellite long distance links. In the 90s, transoceanic fiber optic cables had replaced satellites between most continents. Now fiber has become cost effective for direct connection to the home.

CATV discovered fiber in the mid-1990s and used it first to enhance the reliability of their networks, a big problem. Not long afterwards, CATV system operators discovered they could offer phone and Internet service on that same fiber and greatly enlarged their markets.

The Internet was first transmitted over phone lines which by the late 1980s were mostly fiber. But as Internet traffic grew with the advent of the web and everyone using email, it soon surpassed voice in traffic volume and found the phone system, optimized for voice transmission, highly inefficient for large amounts of digital data. The Internet with its unique transmission protocols became independent from the phone network, although it often used fibers in the same cables.

As cell phones became better and less expensive, creating a gigantic market for personal communications and portable data access, their backbones were built on fiber optics. Frequency allocations for wireless systems were limited so cellular backhaul used fiber to connect to worldwide phone networks.

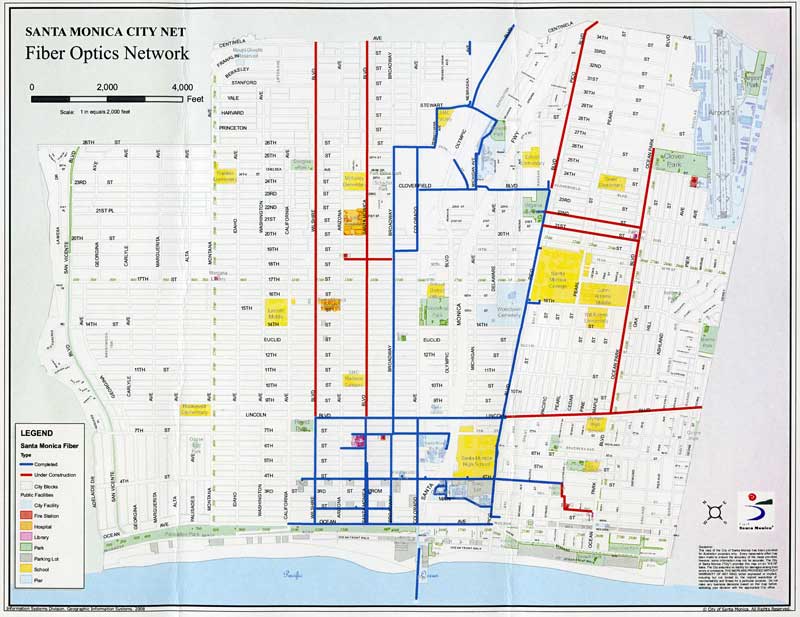

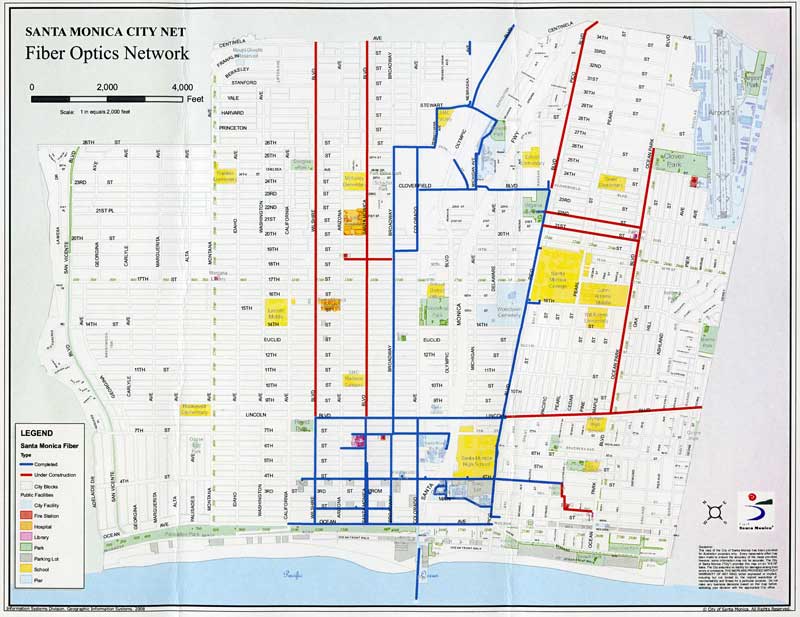

Cities started using fiber optics early in the game, connecting schools, data networks from city agencies and public safety organizations first. Intelligent highway systems led to connecting “smart” traffic light into networks that could optimize traffic flow. When worries about terrorism led to the installation of many surveillance cameras around cities, the distance from cameras to monitoring stations was long enough that connecting them on fiber was much less expensive. Today some even offer direct fiber connections to their residents or businesses.

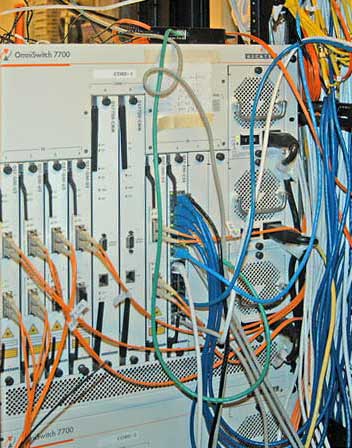

Computer networks (LANs) started using fiber about the same time as the telcos, in the late 1970s. Industrial links were among the first applications as the noise immunity of fiber and its distance capability make it ideal for the factory floor. Connecting graphics displays and mainframe storage links, the predecessors of today's fiber SANs (storage area networks) in data centers, came next. Today fiber is used in most corporate LANs as backbones, connections to desktops for engineering and graphics workstations and many wireless access points.

Utilities also have become big users of fiber. Practically every pipeline or electrical line has fiber running parallel to it or even inside the wires in the case of high voltage electrical distribution lines. Fiber provides communications over the routes and sometimes even includes sensors that keep track of the performance and problems. The electrical utilities are developing “smart grids” to make their power distribution more efficient and these networks depend on fiber for connections.

Other applications developed too: aircraft, ship and automobile data busses, CCTV for security, building automation systems, industrial networks and machinery, even links for consumer digital stereo!

Today fiber optics is either the dominant medium or a logical choice for every communication system. Costs have been reduced so much that fiber to the home is now cost effective, especially since it can offer services (entertainment as well as communications) that no other medium offers.

Fiber optic communications began during the 1970s in R&D labs around the world (Corning, Bell Labs, ITT UK, etc.) and was first installed commercially in Dorset, England by STC and Chicago, IL, USA in 1976 by AT&T. By the early 1980s, the first fiber optic telecommunications networks connected the major cities on each coast of the USA and began being installed throughout the world.

By the mid-80s, with the introduction of the first singlemode fibers, fiber’s bandwidth and distance capabilities made it significantly less expensive than other communications media and it began replacing all the telco copper, microwave and satellite long distance links. In the 90s, transoceanic fiber optic cables had replaced satellites between most continents. Now fiber has become cost effective for direct connection to the home.

CATV discovered fiber in the mid-1990s and used it first to enhance the reliability of their networks, a big problem. Not long afterwards, CATV system operators discovered they could offer phone and Internet service on that same fiber and greatly enlarged their markets.

The Internet was first transmitted over phone lines which by the late 1980s were mostly fiber. But as Internet traffic grew with the advent of the web and everyone using email, it soon surpassed voice in traffic volume and found the phone system, optimized for voice transmission, highly inefficient for large amounts of digital data. The Internet with its unique transmission protocols became independent from the phone network, although it often used fibers in the same cables.

As cell phones became better and less expensive, creating a gigantic market for personal communications and portable data access, their backbones were built on fiber optics. Frequency allocations for wireless systems were limited so cellular backhaul used fiber to connect to worldwide phone networks.

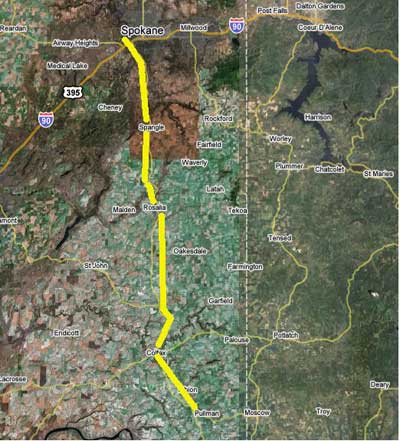

Cities started using fiber optics early in the game, connecting schools, data networks from city agencies and public safety organizations first. Intelligent highway systems led to connecting “smart” traffic light into networks that could optimize traffic flow. When worries about terrorism led to the installation of many surveillance cameras around cities, the distance from cameras to monitoring stations was long enough that connecting them on fiber was much less expensive. Today some even offer direct fiber connections to their residents or businesses.

Computer networks (LANs) started using fiber about the same time as the telcos, in the late 1970s. Industrial links were among the first applications as the noise immunity of fiber and its distance capability make it ideal for the factory floor. Connecting graphics displays and mainframe storage links, the predecessors of today's fiber SANs (storage area networks) in data centers, came next. Today fiber is used in most corporate LANs as backbones, connections to desktops for engineering and graphics workstations and many wireless access points.

Utilities also have become big users of fiber. Practically every pipeline or electrical line has fiber running parallel to it or even inside the wires in the case of high voltage electrical distribution lines. Fiber provides communications over the routes and sometimes even includes sensors that keep track of the performance and problems. The electrical utilities are developing “smart grids” to make their power distribution more efficient and these networks depend on fiber for connections.

Other applications developed too: aircraft, ship and automobile data busses, CCTV for security, building automation systems, industrial networks and machinery, even links for consumer digital stereo!

Today fiber optics is either the dominant medium or a logical choice for every communication system. Costs have been reduced so much that fiber to the home is now cost effective, especially since it can offer services (entertainment as well as communications) that no other medium offers.

Whenever

you read an article or talk to someone about fiber optics, you need to

know the point of view. We're mainly concerned with communications

fiber optics, but it's also used in medical or nondestructive testing

inspection and lighting. Fiber optics, you see, is not all the

same.

Even

in communications, we have "outside plant" fiber optics as used in

telephone networks, CATV, metropolitan networks, utilities, etc. or

"premises" fiber optics as found in buildings and campuses.Just like "wire" which can mean lots of different things

- power, security, HVAC, CCTV, LAN or telephone - fiber optics

is not all the same. And this can be a big source of confusion

to the novice. Lets define our terms.

Outside Plant (OSP)

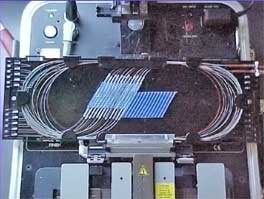

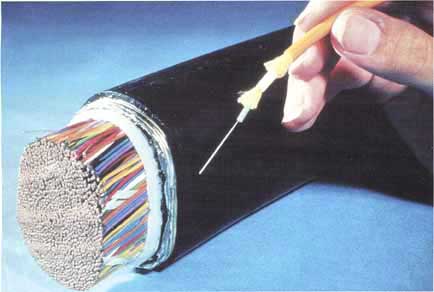

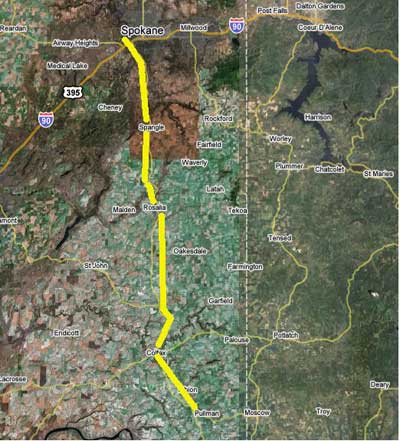

Telephone companies, CATV and the Internet all use lots of fiber optics, virtually all of which is singlemode fiber and most of which is outside buildings. It hangs from poles, is buried underground, pulled through conduit or is even submerged underwater. Most of it goes relatively long distances, from a few hundred feet to hundreds of miles.

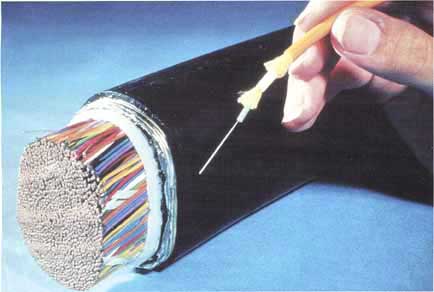

Outside plant cables often have very high fiber counts, up to 288 fibers or more. Cable designs are optimized for the application: cables in conduit for pulling tension and resisting moisture, buried cables for resisting moisture and rodent damage, aerial for continuous tension and extreme weather and undersea for resisting moisture penetration. Installation requires special equipment like pullers or plows, and even trailers to carry giant spools of cable.

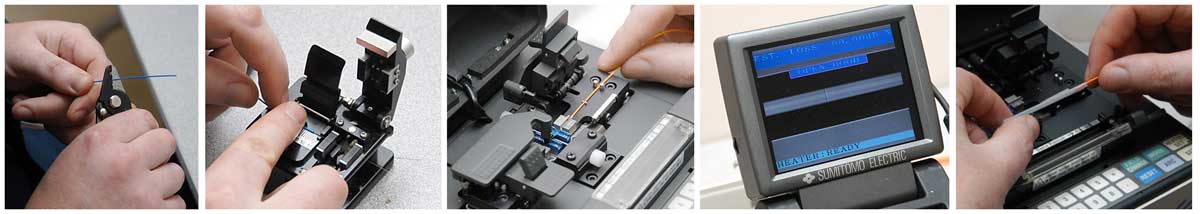

Long distances mean cables are spliced together, since cables are not manufactured in lengths longer than about 45 km (2.-3 miles), and most splices are by fusion splicing. Connectors (generally SC or LC styles) on factory made pigtails are spliced onto the end of the cable. After installation, every fiber and every splice is tested with an OTDR.

If this sounds expensive, you are right! The installer usually has a temperature controlled van or trailer for splicing and/or a bucket truck. Investments in fusion splicers, OTDRs and other equipment can be quite expensive.

Most outside plant telephone installs are done by the telco themselves, while a small number of large, specialized installers do CATV, utility and municipal work.

Telephone companies, CATV and the Internet all use lots of fiber optics, virtually all of which is singlemode fiber and most of which is outside buildings. It hangs from poles, is buried underground, pulled through conduit or is even submerged underwater. Most of it goes relatively long distances, from a few hundred feet to hundreds of miles.

Outside plant cables often have very high fiber counts, up to 288 fibers or more. Cable designs are optimized for the application: cables in conduit for pulling tension and resisting moisture, buried cables for resisting moisture and rodent damage, aerial for continuous tension and extreme weather and undersea for resisting moisture penetration. Installation requires special equipment like pullers or plows, and even trailers to carry giant spools of cable.

Long distances mean cables are spliced together, since cables are not manufactured in lengths longer than about 45 km (2.-3 miles), and most splices are by fusion splicing. Connectors (generally SC or LC styles) on factory made pigtails are spliced onto the end of the cable. After installation, every fiber and every splice is tested with an OTDR.

If this sounds expensive, you are right! The installer usually has a temperature controlled van or trailer for splicing and/or a bucket truck. Investments in fusion splicers, OTDRs and other equipment can be quite expensive.

Most outside plant telephone installs are done by the telco themselves, while a small number of large, specialized installers do CATV, utility and municipal work.

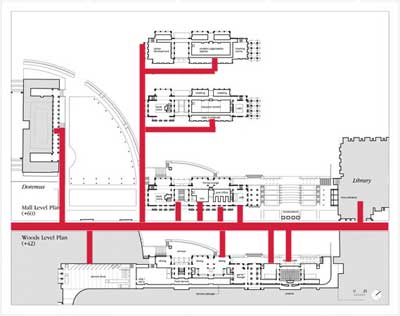

Premises Cabling

By contrast, premises cabling- cabling installed in a building

or campus - involves shorter lengths, rarely longer than a few

hundred feet, typically with fewer fibers per cable. The fiber

is mostly multimode, except for the enlightened user who installs

hybrid cable with both multimode and singlemode fibers for future high bandwidth applications.

By contrast, premises cabling- cabling installed in a building

or campus - involves shorter lengths, rarely longer than a few

hundred feet, typically with fewer fibers per cable. The fiber

is mostly multimode, except for the enlightened user who installs

hybrid cable with both multimode and singlemode fibers for future high bandwidth applications.

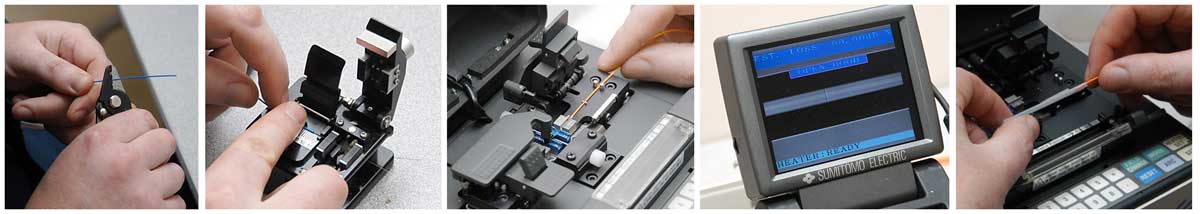

Splicing is practically unknown in premises applications. Cables between buildings can be bought with double jackets, PE for outside plant protection over PVC for building applications requiring flame retardant cable jackets, so cables can be run continuously between buildings. Today's connectors often have lower loss than splices, and patch panels give more flexibility for moves, adds and changes.

Most connectors are SC or ST style with LCs becoming more popular. Termination is by installing connectors directly on the ends of the fibers, primarily using adhesive or sometimes prepolished splice techniques. Testing is done by a source and meter, but every installer should have a flashlight type tracer to check fiber continuity and connection.

Unlike the outside plant technician, the premises cable installer (who is often also installing the power cable and Cat 5/6 for LANs too!) probably has an investment of less than $2,000 in tools and test equipment.

There are thousands of cabling installers who do fiber optic work. They've found out it isn't "rocket science," and their small initial investment in training, tools and test equipment is rapidly paid back.

Few installers do both outside plant and premises cabling. The companies that do are usually very large and often have separate divisions doing each with different personnel. Most contractors do nothing but premises cabling.

By contrast, premises cabling- cabling installed in a building

or campus - involves shorter lengths, rarely longer than a few

hundred feet, typically with fewer fibers per cable. The fiber

is mostly multimode, except for the enlightened user who installs

hybrid cable with both multimode and singlemode fibers for future high bandwidth applications.

By contrast, premises cabling- cabling installed in a building

or campus - involves shorter lengths, rarely longer than a few

hundred feet, typically with fewer fibers per cable. The fiber

is mostly multimode, except for the enlightened user who installs

hybrid cable with both multimode and singlemode fibers for future high bandwidth applications.Splicing is practically unknown in premises applications. Cables between buildings can be bought with double jackets, PE for outside plant protection over PVC for building applications requiring flame retardant cable jackets, so cables can be run continuously between buildings. Today's connectors often have lower loss than splices, and patch panels give more flexibility for moves, adds and changes.

Most connectors are SC or ST style with LCs becoming more popular. Termination is by installing connectors directly on the ends of the fibers, primarily using adhesive or sometimes prepolished splice techniques. Testing is done by a source and meter, but every installer should have a flashlight type tracer to check fiber continuity and connection.

Unlike the outside plant technician, the premises cable installer (who is often also installing the power cable and Cat 5/6 for LANs too!) probably has an investment of less than $2,000 in tools and test equipment.

There are thousands of cabling installers who do fiber optic work. They've found out it isn't "rocket science," and their small initial investment in training, tools and test equipment is rapidly paid back.

Few installers do both outside plant and premises cabling. The companies that do are usually very large and often have separate divisions doing each with different personnel. Most contractors do nothing but premises cabling.

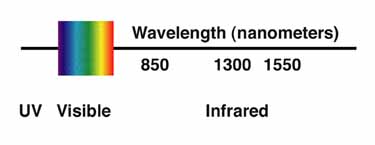

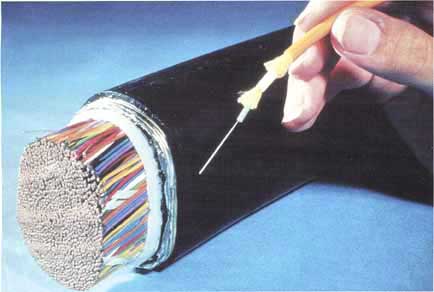

- The biggest advantage of optical fiber is the fact it is the most cost effective means of transporting information. Fiber can transport more information longer distances in less time than any other communications medium, as the photo on the left from the late 1970s illustrates so well.

- The bandwidth and distance capability of fiber means that fewer cables are needed, fewer repeaters, less power and less maintenance. In addition, fiber is unaffected by the interference of electromagnetic radiation which makes it possible to transmit information and data with less noise and less error. Fiber is lighter than copper wires which makes it popular for aircraft and automotive applications.

Wireless

was used as a long distance medium until fiber became available, but

wireless is limited by available transmission frequencies so it was

dropped as a long distance medium. While local wireless has grown

exponentially, it uses fiber as a backbone and connection to the

international phone system and Internet.

- These advantages makes the use of optical fiber the most logical choice in data transmission.

- Twenty

five years ago, fiber was just being introduced. It was expensive and

required PhD's from Bell Labs to install it while copper wire was easy

to install. Today most communications installers do fiber and wireless as well as copper.

Because fiber is so powerful, at today's network speeds fiber still has plenty of headroom and users can look to the future of ten to one hundred gigabit speeds with confidence. Telcos use DSL over copper today but it's very limited in bandwidth over typical subscriber connection lengths and many older copper wires will not support DSL speeds, leading to the adoption of fiber to the home. Copper gigabit Ethernet can work over short cables in LANs or but only if it is carefully installed and tested. - But isn't fiber more expensive? Telcos and CATV operators use fiber because it's actually much cheaper. They optimize the architecture of their network to take advantage of fiber's speed and distance advantages. In LANs, you need to follow the EIA/TIA 568 standard for "centralized fiber" to optimize the fiber usage, and then it can be cheaper than copper. Installing the proper fiber today in a LAN will give you good chance of being able to handle new network speeds for years to come. One fiber, FDDI grade 62.5/125, outlasted 9 generations of copper! See Networks for more information on how to use fiber.

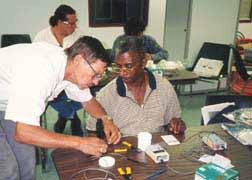

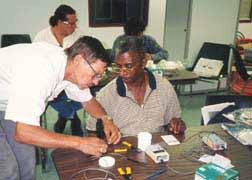

- The Secret To Success In Fiber

Optics Is Training!

You wouldn't try to drive a truck or fly a plane without taking lessons. Likewise for improving your golf or tennis game. Well, the secret to fiber optics is training too. With some basic knowledge and hands-on practice gained in a training course, fiber is pretty easy to install.

Where to Get Training?

Well, you can start right here at the FOA, of course! This reference guide is

designed to get you started and you should have "hands-on" training

leading to a recognized certification program like the FOA CFOT to be

qualified to install fiber. Check the website

of the Fiber Optic Association at http://www.TheFOA.org.

for the leading fiber optic certification program in the industry.

Finally, take advantage of the training offered by manufacturers

and distributors whenever you can, often this training is free

or cheap! (but limited to the manufacturer's equipment

of course.)

- How about Certification?

- That's what the FOA is all about. We have hundreds of FOA-approved schools offering FOA certifications. Over 30,000 students have been certified by FOA schools (7/2010.)Around the world, FOA is recognized as the leader in fiber optic education and certification.

- Standards

- The

adoption of any technology depends on having workable standards

to insure product compatibility. Most of what we call standards are

voluntary standards created by industry groups. Standards are not

"codes" or actual laws that you must follow to be in compliance with

local ordinances but sensible guidelines to ensure proper operation of

communications systems. Standards are often developed by groups within

each country, like EIA/TIA or IEEE in the US, but are increasingly

becoming international under the auspices of ISO and IEC.

Standards like EIA/TIA 568 ( from the Electronic Industries Alliance/ Telecommunications Industry Association in the US) which covers all of the things you need to know to install a standard premises cabling network are good guidelines for designs and should be followed to ensure interoperability.

Primary measurement standards like for optical power measurements are set by standards organizations in each country like NIST (the US National Institute of Standards and Technology) and coordinated worldwide.

The only common "mandatory standard" in the US - we call them codes - is the NEC 770 (National Electrical Code). The NEC specifies fire prevention standards for fiber optic cables. Other countries have similar codes for building safety. If an indoor cable doesn't have a NEC rating - don't install it - it won't pass inspection! - A listing of the EIA/TIA standards is on the website of The Fiber Optic Association. Information on the EIA/TIA standards can be found on the website of most of the suppliers of structured cabling hardware.

.

You

might think that eye damage from working with lasers would be the big

concern in fiber optic installations. The reality is that high power

lasers burning holes in metal or burning off warts mostly have little

relevance to your typical fiber optic installation. Optical sources

used in fiber optics are generally of much lower power levels (The

exception is high power DWDM or CATV systems). Of course, you should

always be careful with your eyes, especially when using a fiber optic

microscope which can concentrate all the light from the fiber into your

eye. NEVER look into a fiber unless you know no light is present - use

a power meter to check it - and anyway, the light is in the infrared

and you can't see anything anyway!

The real safety lecture will

always be about small scraps of glass cleaved off the ends of

the fibers being terminated or spliced. These scraps are very

dangerous! The cleaved ends are extremely sharp and can easily

penetrate your skin. If they get into your eyes, they are very

hard to flush out. Don't even think about what happens if you

eat one. Always wear safety glasses whenever working with fiber and always carefully dispose of all fiber scraps!

Always follow these rules when

working with fiber.

1. Always wear safety glasses to protect your eyes from fiber scraps.

2. Dispose of all scraps properly. Always use a properly marked container to dispose of later and work on a black pad which makes the slivers of glass easier to spot.

3. Do not drop them on the floor where they will stick in carpets or shoes and be carried elsewhere.

4. Do not eat or drink anywhere near the work area.

1. Always wear safety glasses to protect your eyes from fiber scraps.

2. Dispose of all scraps properly. Always use a properly marked container to dispose of later and work on a black pad which makes the slivers of glass easier to spot.

3. Do not drop them on the floor where they will stick in carpets or shoes and be carried elsewhere.

4. Do not eat or drink anywhere near the work area.

Fiber

optic splicing and termination use various chemical adhesives and

cleaners as part of the processes. Follow the instructions for use

(detailed on the chemical's MSDS - material safety data sheet)

carefully. Remember, even simple isopropyl alcohol, used as a cleaner,

is flammable.

.

Zero Tolerance for Dirt

With fiber optics, our tolerance

to dirt is near zero. Airborne particles are about the size of

the core of SM fiber- they absorb lots of light and may scratch

connectors if not removed! Dirt on connectors is the biggest

cause of scratches on polished connectors and high loss measurements!

1. Try to work in a clean area.

Avoid working around heating outlets, as they blow dust all over

you

2. Always keep dust caps on connectors, bulkhead splices, patch panels or anything else that is going to have a connection made with it.

3. Use special fiber optic cleaners or lint free pads and isopropyl alcohol to clean the connectors.

4. Ferrules on the connectors/cables used for testing will get dirty by scraping off the material of the alignment sleeve in the splice bushing - creating an attenuator. You can see the front edge of the connector ferrule getting black! Use the metal or ceramic alignment sleeve bulkheads only for testing.

2. Always keep dust caps on connectors, bulkhead splices, patch panels or anything else that is going to have a connection made with it.

3. Use special fiber optic cleaners or lint free pads and isopropyl alcohol to clean the connectors.

4. Ferrules on the connectors/cables used for testing will get dirty by scraping off the material of the alignment sleeve in the splice bushing - creating an attenuator. You can see the front edge of the connector ferrule getting black! Use the metal or ceramic alignment sleeve bulkheads only for testing.

Fiber Optic Jargon

The

key to understanding any technology is understanding the language of

the technology – the jargon. We’ve started this book with an overview

of fiber jargon to introduce you to the language of fiber optics and

help you understand what you will be reading in the book. While we try

to use the most common terminology, some particular applications for

optical fiber have their own specialized terms, and when possible, we

will try to include those terms also. We suggest you read this section

first to help your understanding of the rest of the book and refer back

to it when you encounter a term that you do not recognize. You can also

use the definitions in the Glossary or the FOA Online Reference Guide for more explanations.

What is fiber optics?

Fiber optics is sending signals from one location to another in the form of modulated light guided

through hair-thin fibers of glass or plastic. These signals can be

analog or digital and voice, data or video information. Fiber

can transport more information longer distances in less time

than any copper wire or wireless method.

It's powerful and very

fast - offering more bandwidth than any other form of communication!

First you need to know the language

- the "jargon" - here's a list of terms you should

know:

The Metric System

- Fiber Optics, as an international technology, utilizes the metric system as the standard form of measurement.

- Several of the more common terms:

- Meter: 3.28 feet, 39.37 inches. Fiber optic cable lengths are generally expressed in meters or kilometers.

Kilometer: 1000 meters / 3,281 feet / 0.62 miles.

Micron: 1/1,000,000 th of a meter. 25 microns equal 0.001 inch. This is the common term of measurement for fiber diameters, most of which are 125 microns in outside diameter.

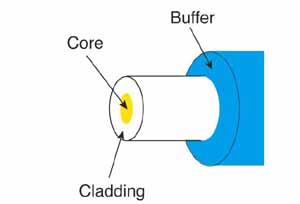

Nanometer: One billionth of one meter. This term is commonly used in the fiber optics industry to express wavelength of transmitted light, e.g 850 or 1300 nm.

Optical Fiber: Thin strands of highly transparent glass

or

plastic that guide light.

plastic that guide light.

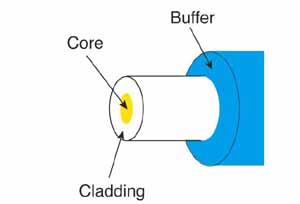

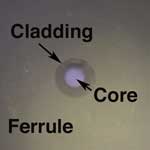

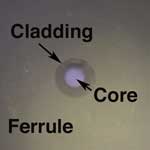

Core: The center of the fiber where the light is transmitted.

Cladding: The outside optical layer of the fiber

that traps the light in the core and guides it along - even through

curves.

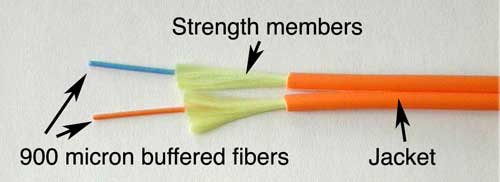

Buffer coating or primary

buffer coating: A hard plastic

coating on the outside of the fiber that protects the glass from

moisture or physical damage. The buffer is what one strips off the fiber for termination or splicing.

Mode: A single "electromagnetic field pattern" (think

of a ray of light) that travels in fiber.

Multimode fiber: has a larger core (almost always 50 or 62.5

microns - a micron is one one millionth of a meter) and is used with laser or LED sources at wavelengths of 850

and 1300 nm for short distance, lower speed data networks like LANs.

Singlemode fiber:

has a much smaller core, only about 8-9 microns, so it only transmits one

mode. Singlemode is used for telephony (long distance, metropolitan and

fiber to the home) and CATV with laser sources at 1310 to 1550 nm. It

can go very long distances at very high speeds.

Fiber ID: Fibers

are identified by their core and cladding diameters expressed in

microns (one millionth of a meter), e.g. 50/125 micron multimode fiber. Most

multimode and singlemode fibers have an outside diameter of 125 microns

- about 0.005 - 5 thousandths of an inch - just slightly larger than a

human hair. International standards also have names for fibers that

call out detailed specifications that include bandwidth capability or other special characteristics.

Plastic optical fiber (POF): is a large core (usually 1mm) multimode

fiber that can be used for short, low speed networks. POF is

used in consumer HiFi and as part of a

standard for car communication systems called MOST (go to http://www.mostcooperation.com/) More on POF.

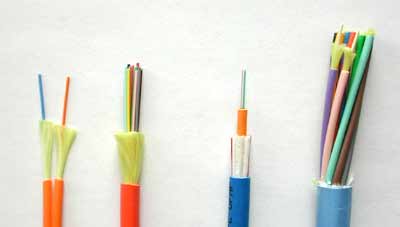

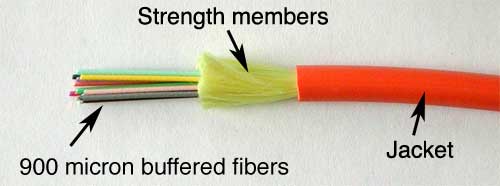

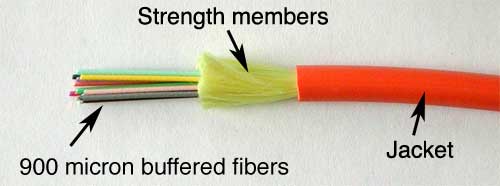

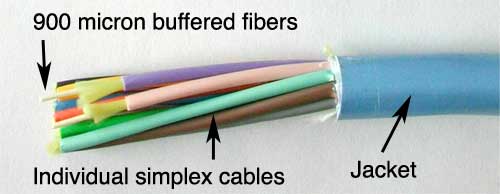

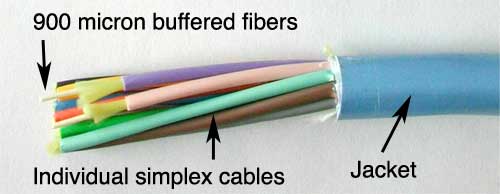

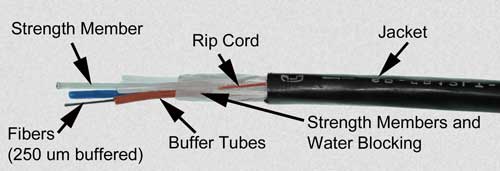

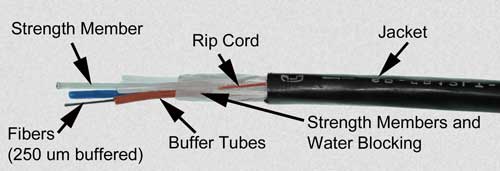

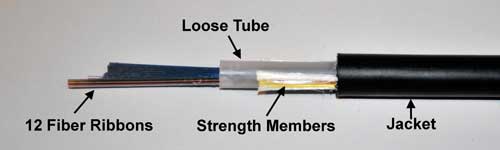

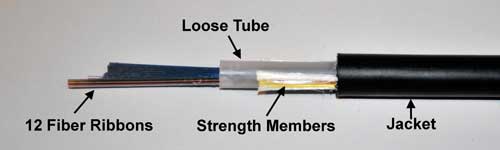

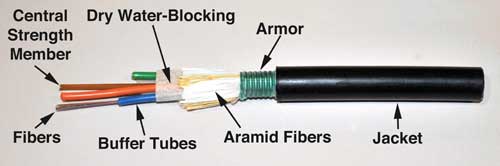

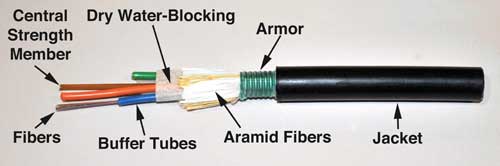

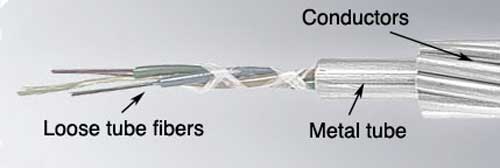

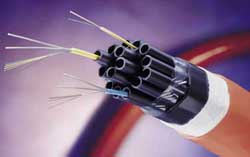

Cable:

Cable provides protection to the fiber from stress during installation

and from the environment once it is installed. Cables may contain from

only one to hundreds of fibers inside. Cables come in three varieties:

tight buffer with a thick plastic coating on the fibers for protection,

used mainly indoors, loose-tube, where fibers with only a primary

buffer coating are inside plastic tubes, and ribbon, where fibers are

made into ribbons to allow small cables with the largest numbers of

fibers.

Jacket: The tough outer covering on the cable. Cables installed inside buildings must meet fire codes by using special jacketing materials.

Strength members: Aramid fibers (Kevlar is the duPont

trade name) used to pull the cable. The term is also used for

the fiberglass rod in some cables used to stiffen it to prevent

kinking.

Armor: Prevents

crushing and discourages rodents from damaging cable by chewing through

it. Some cable called armored also includes layers of strengthening

wires for use in extreme environments such as encountered by submarine

cables.

Sheath: A term used for the combination of the jacket, armor and any other elements used to protect the fibers in a cable.

Sheath: A term used for the combination of the jacket, armor and any other elements used to protect the fibers in a cable.

Outside Plant InstallationsOutside plant installations fall into four general categories, depending on the placement of the cable. Each requires cable types chosen for the installation and specialized equipment for placement.

Underground: Cables placed underground in conduit, often inside innerduct pulled in the conduit. Cables can also be blown into duct lines installed by trenching or plowing.

Direct Buried: Cable placed underground without conduit, placed in trenches, plowed into the ground or installed by directional boring.

Aerial: Cable placed above ground on utility poles.

Submarine: Cables placed underwater, including those in shallow water such as lakes or rivers as well as those used for ocean crossings.

Connector: A non-permanent device for connecting

two fibers in a non-permanent joint or connect fibers to equipment. Connectors are expected

to be disconnected occasionally for testing or rerouting. (Parts for an ST connector

are shown.)

Ferrule: A tube which holds a fiber for alignment, usually part of a connector

Splice: a permanent joint between two fibers

Mechanical Splice: A splice where the fibers are aligned

created by mechanical means

Fusion Splice: A splice created by welding or fusing

two fibers together

Fusion Splicer: An instrument that splices fibers by

fusing or welding them, typically by electrical arc.

Hardware: Terminations and Splices require hardware for

protection and management: patch panels, splice closures (shown below), etc.

Terms you use when you want to specity fibers or make measurements of fiber optic components or cable plants:

Attenuation:

The reduction in optical power as it passes along a fiber, usually

expressed in decibels (dB). For fibers, we talk about attenuation

coefficient or attenuation per unit length, in dB/km. See optical loss

Bandwidth: The range of signal frequencies or

bit rate within which a fiber optic component, link or network

will operate.

Decibels (dB): A unit of measurement of optical power

which indicates relative power. A -10 dB means a reduction in

power by 10 times, -20 dB means another 10 times or 100 times

overall, -30 means another 10 times or 1000 times overall and

so on.

dB: Optical power referenced an arbitrary zero level, used to measure loss

dBm: Optical power referenced to 1 milliwatt, used to measure optical power from transmitters or at receivers. See optical power.

Optical Loss: The amount of optical power lost as

light is transmitted through fiber, splices, couplers, etc, expressed

in "dB."

Optical Power: is measured in "dBm", or decibels

referenced to one miliwatt of power. while loss is a relative

reading, optical power is an absolute measurement, referenced

to standards. You measure absolute power to test transmitters

or receivers and relative power to test loss.

Dispersion: Pulse spreading caused by modes in multimode fiber (modal dispersion), the difference in speed of light of different wavelengths (CD or chromatic dispersion in multimode or singlemode fiber ) or polarization (PMD or polarization mode dispersion in singlemode)

Dispersion: Pulse spreading caused by modes in multimode fiber (modal dispersion), the difference in speed of light of different wavelengths (CD or chromatic dispersion in multimode or singlemode fiber ) or polarization (PMD or polarization mode dispersion in singlemode)

Scattering: The change of direction of light after

striking small particles that causes the majority of loss in optical fibers and

is used to make measurements by an OTDR

Wavelength: A term for the color of light, usually

expressed in nanometers (nm) or microns (m). Fiber is mostly

used in the infrared region where the light is invisible to the

human eye. Most fiber specifications (attenuation, dispersion) are dependent on wavelength.

Dispersion:

Pulse spreading caused by modes in multimode fiber (modal dispersion), the difference in

speed of light of different wavelengths (CD or chromatic dispersion in multimode or singlemode fiber ) and

polarization (PMD or polarization mode dispersion in singlemode)

Terms that describe the tools needed for installation and termination:

Jacket Slitter or Stripper: A cutter for removing the heavy outside

jacket of cables

Fiber Stripper: A precise stripper used to remove the

buffer coating of the fiber itself for termination. There at

three types in common use, called by their trade names: "Miller

Stripper", "No-Nik" and "Micro Strip."

Cleaver: A tool that precisely "breaks"

the fiber to produce a flat end for polishing or splicing.

Scribe: A hard, sharp tool that scratches the fiber to allow cleaving.

Polishing Puck: for connectors that require polishing,

the puck holds the connector in proper alignment to the polishing

film.

Polishing Film: Fine grit film used to polish the end

of the connector ferrule.

Crimper: A tool that crimps the connector to the aramid

fibers in the cable to add mechanical strength.

Fusion Splicer: An instrument that welds two fibers together into a permanent joint.

Terms that describe fiber optic test equipment:

Optical Power Meter: An instrument that measures optical

power from the end of a fiber

Test Source: an instrument that uses a laser or

LED to send an optical signal into fiber for testing loss of

the fiber

Optical Loss Test Set (OLTS):

A measurement instrument that includes both a meter and source used for

measuring insertion loss of installed cable plants or individual cables. ALso called light source and power meter (LSPM.)

Reference Test Cables: short, single fiber cables with connectors

on both ends, used to test unknown cables.

Mating Adapter: also called splice bushing or couplers,

allow two cables with connectors to mate.

Fiber Tracer: An visible light source (LED or flashlight) that allows visual checking

of continuity and tracing for correct connections such as duplex connector polarity

Visual Fault Locator: A high-powered visible laser light source that allows continuity testing, fiber tracing and location of faults near the end of the cable.

Inspection Microscope: used to inspect the end surface of

a connector for faults such as scratches, polish or dirt.

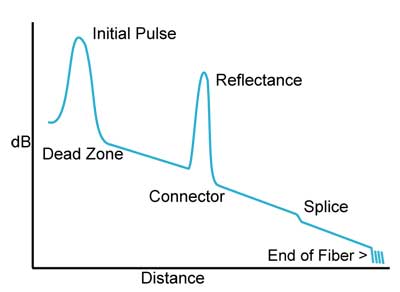

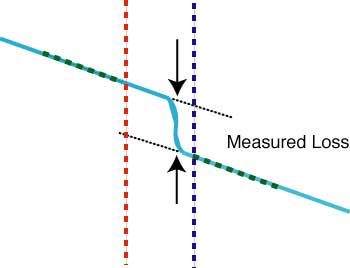

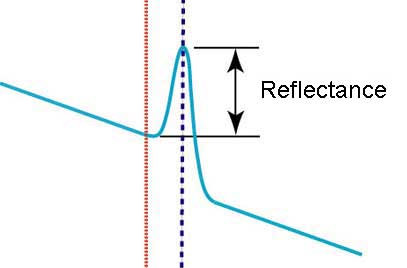

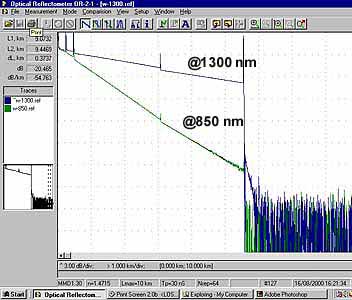

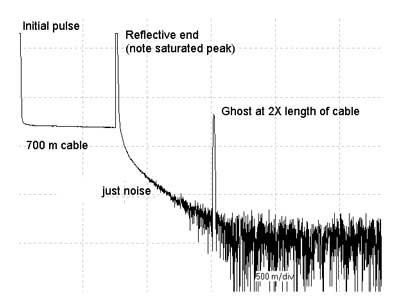

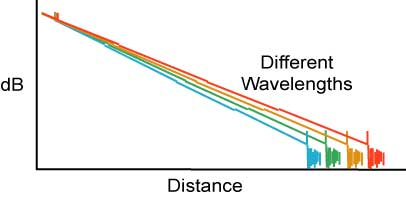

Optical Time Domain Reflectometer (OTDR):

An instrument that uses backscattered light to take a snapshot of an

optical fiber which can be used to measure fiber length, splice loss,

fiber attenuation and for fault location in optical fiber from only one

end of the cable.

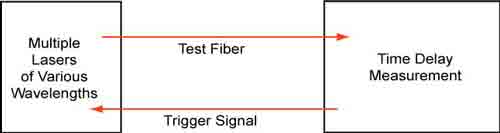

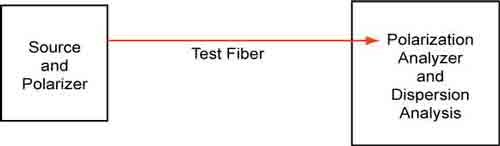

Specialized Testers: Long

distance networks may need testing for chromatic dispersion (CD) and

polarization mode dispersion (PMD). Systems using wavelength-division

multiplexing may need testing for spectral attenuation. Each

performance factor has a specialized tester for that specification.

Fiber In Communications

- Jump to:

Internet

- Telephone

CATV

- Security

Utility

Metropolitan

Premises

Fiber

has become the communications medium of choice for telephones, cell

phones, CATV, LAN backbones, security cameras, industrial networks,

just about everything.

Why use fiber?

The

biggest advantage of optical fiber is the fact it is the most cost

effective means of transporting information. FIber can transport more

information longer distances in less time than any other

communications medium, as the photo on the left from the late 1970s

illustrates so well. The bandwidth and distance capability of fiber

means that fewer cables are needed, fewer repeaters, less power and

less maintenance. In addition, fiber is unaffected by the interference

of electromagnetic radiation which makes it possible to transmit

information and data with less noise and less error. Fiber is lighter

than copper wires which makes it popular for aircraft and automotive

applications. These advantages open up the doors for many other

advantages that make the use of optical fiber the most logical choice

in data transmission.

These

advantages have led to fiber becoming the transport medium of choice

for practically all data, voice and video communications.

Both

telcos and CATV operators use fiber for economic reasons, but their

cost justification requires adopting new network architectures to take

advantage of fiber's strengths. LAN and premises network designers and

installers now realize that they must also adopt new network

architectures too. A properly designed premises cabling network can

also be less expensive when done in fiber instead of copper. Conversion

from copper networks is easy with media converters, gadgets that

convert most types of systems to fiber optics. Even adding the cost of

the media converters, the fiber optic network will usually be less than

copper when the proper architecture is used.

Fiber Optic Communication Networks

Outside Plant Networks

Telephone Networks

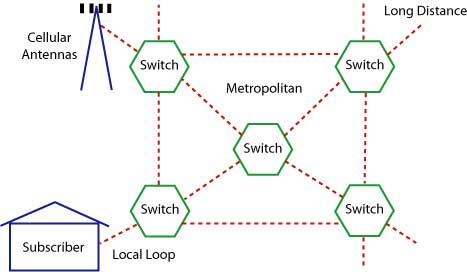

Telephone networks were the first major users of fiber optics. Fiber optic links were used to replace copper or digital radio links between telephone switches, beginning with long distance links, called long lines, where fiber's distance and bandwidth capabilities made fiber significantly more cost effective. Telcos use fiber to connect all their central offices and long distance switches because it has thousands of times the bandwidth of copper wire and can carry signals hundreds of times further before needing a repeater - making the cost of a phone connection over fiber only a few percent of the cost of the same connection on copper.

After

long distance links were converted to fiber, telcos began replacing

shorter links between switches with fiber, for example between switches

in the same metropolitan area. Today, with the exception of some rugged

or remote locations, the entire telephone backbone is fiber optics.

Cables on the land are run underground, direct buried or aerially,

depending on the geography and local regulations. Connections around

the world are run primarily on undersea cables which now link every

continent and most island nations with the exception of Antarctica.

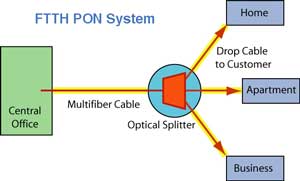

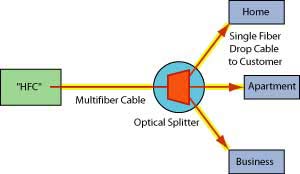

After

long distance links were converted to fiber, telcos began replacing

shorter links between switches with fiber, for example between switches

in the same metropolitan area. Today, practically all the telephone

networks have been converted to fiber. Telcos and other groups are now

running fiber right to the home, (FTTH) using low cost passive optical

network (PON) systems that use splitters to share the cost of some

fiber optic components among as many as 32 subscribers. More on FTTH, FTTH PON types and FTTH network architecture.

Even

cell phone networks have fiber

backbones. It's more efficient and less expensive than using precious

wireless bandwidth for backbone connections. Cell phone towers with

many antennas will have large cable trays or pedestals where fiber

cables connect to the antenna electronics.

The Internet

The Internet

The

Internet has always been based on a fiber optic backbone. It started as

part of the telephone network when it was primarily voice and data

traffic was mixed into the total traffic. But data has

become the largest communications network as data traffic has outgrown

voice traffic. The Internet now transmits user communications, e.g.

requesting and downloading web pages or email, peer-to-peer

transmissions, streaming video and massive data transfers between data

centers. Large Internet providers are moving toward dedicated Internet

networks that do not have the high overhead of telco networks which are

burdened with transporting dozens of different types of communications

services still being supported by the telco system providers. Now the

telcos are moving their voice communications to

Internet protocol (IP) for lower costs.

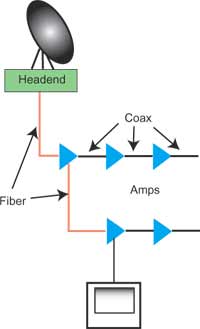

CATVMost CATV systems are using fiber backbones too. CATV companies use fiber because it give them greater reliability and the opportunity to offer new services, like phone service and Internet connections.

CATV used to have a terrible reputation for reliability, not really a problem with service but with network topology. CATV uses very high frequency analog signals, up to 1 GHz, which has high attenuation over coax cable. For a city-wide system, CATV needed many amplifiers (repeaters) to reach the users at the end of the system; 15 or more we common. Amplifiers failed often, meaning that subscriber downstream of the failed amp lost signal. Finding and fixing failed amps was difficult and time consuming, causing subscriber complaints.

The

development of highly linear distributed feedback (DFB) lasers allowed

CATV systems to be converted to analog optical systems.

CATV companies "overbuild" with fiber. They connect their headends with

fiber and then take fiber into the neighborhood. They lash the fiber

cable onto the aerial "hardline" coax used for the rest of the network

or pull it in the same conduit underground. The fiber allows them to

break their network into smaller service areas, typically fewer than 4 amplifiers deep, that prevent large

numbers of customers from being affected in an outage, making their network more

reliable and easier to troubleshoot, providing better service and

customer relations.

The fiber also gives CATV operators a return path which they use for Internet and telephone connections, increasing their revenue potential. Most current CATV systems still use AM (analog) systems which simply convert the electrical TV signals into optical signals. Look for them to convert to more digital transmission in the future.

The fiber also gives CATV operators a return path which they use for Internet and telephone connections, increasing their revenue potential. Most current CATV systems still use AM (analog) systems which simply convert the electrical TV signals into optical signals. Look for them to convert to more digital transmission in the future.

CATV is even developing its own version of fiber to the home called RF over glass (RFOG.) This uses a interface at the home that is like a cable modem but with an optical input that accepts the same analog radio frequency (RF) signals that are used throughout the HFC network.

Security systems can have a wider reach and are more secure on fiber. Practically any system today has a fiber optic option. CCTV cameras used for surveillance often use fiber for it's distance capability and security, especially in large buildings like airports and around cities with metropolitan networks. Fiber also has much more bandwidth than coax so several cameras can be multiplexed onto one fiber. Bidirectional links allow controlling pan, zoom and tilt (PZT) cameras. Other security devices like intrusion alarms or perimeter alarms can utilize fiber and some even use fiber optic sensors.

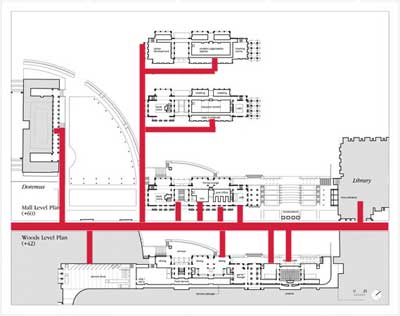

Metropolitan Networks

Many cities have incorporated fiber optics into their communications networks. Metropolitan networks use fiber for many other applications besides CCTV surveillance cameras, including connecting public service agencies such as fire, police and other emergency services, hospitals, schools, as well as connecting municipal WiFi and traffic management systems as shown in the photo. Cities can install cables to strategic locations so various services can share the fibers in the cables, saving installation costs. Cities are also learning to bury extra conduits every time a roadway is dug up so when cables need installing, no further construction is needed.

Utility Networks

Utilities use fiber for communications, CCTV surveillance and network management. Electrical utilities have used fiber optics for decades for communications and managing their distribution systems. They realized quickly that fiber’s immunity to electromagnetic interference would allow them to operate communications and control networks in close proximity to electrical circuits without problems. Electrical utilities take full advantage of fiber's immunity to noise also, even running fiber inside high voltage power distribution cables. Some utilities install fibers inside their high voltage distribution networks using optical power ground wire (OPGW) and lease fibers to other telecommunications companies. Utilities use fiber in one non-communications application; fiber optic sensors allow monitoring high voltage and current in their distribution systems. The interest in "smart grid" management of power distribution to enhance efficiency is based on using fiber optics for network management.

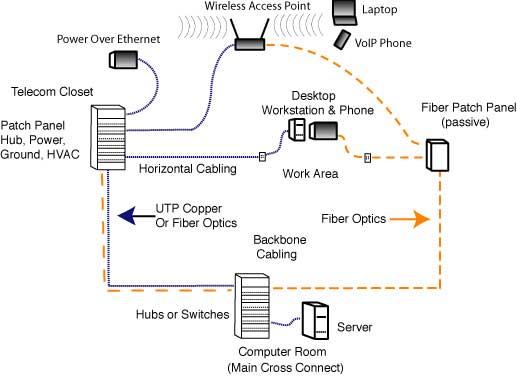

Premises Networks

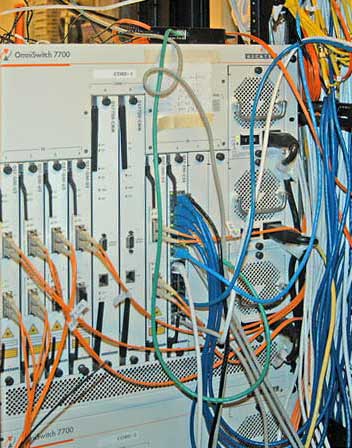

Premises networks, mostly computer LANs (local area networks) use fiber optics primarily in the backbone but increasingly to the desk and to connect wireless access points. The LAN backbone often needs longer distances than copper cable (Cat 5/5e/6/6A) can provide and of course, the fiber offers higher bandwidth for future expansion. Fiber's ability to handle network upgrades meant that one fiber type outlived nine generations of copper cables in LANs. A new fiber type (OM3) offers future potential for upgrades while copper continues to struggle with network speed increases.

Until recently large corporate LANs use fiber backbones with copper wire to the desktop. LAN switches and hubs are usually available with fiber optic ports but PCs have interfaces to Ethernet on copper. Inexpensive media converters allow connecting PCs to fiber. Fiber to the desk can be cost effective if properly designed using centralized fiber architecture without local switching in the telecom closet, but many users no longer want to be "tethered" to a network cable. Desktop computer sales are declining and laptops are the PC of choice for most users, with wireless connections to the network. Generally only high data users like engineers and graphics designers use desktop workstations; everybody else gets a wireless-connected laptop.

Centralized Fiber LANs

- When most contractors and end users look at fiber optics versus Category-rated UTP cabling for a LAN, they compare the same old copper LAN with fiber directly replacing the copper links. The installed cost of a fiber optic cable plant comparable to the cost of Cat 5/6/6A, but fiber often requires medial conversion electronics which add cost to the link for fiber.

- However, the real difference comes if you use a centralized fiber optic network - shown on the right of the diagram above. Since fiber does not have the 90 meter distance limitation of UTP cable, you can place all electronics in one location in or near the computer room. The telecom room is only used for passive connection of backbone fiber optic cables, so no power, UPS, ground or air conditioning is needed. These auxiliary services, necessary with Cat 5 hubs, cost a tremendous amount of money in each telecom room. If designing a new building, you do not even need the cost of the telecom room itself.

- In addition, having all the fiber optic hubs in one location means better utilization of the hardware, with fewer unused ports. Since ports in modular hubs must be added in modules of 8 or 16, it's not uncommon with a hub in a telecom closet to have many of the ports in a module empty . With a centralized fiber system, you can add modules more efficiently as you are supporting many more desktop locations but need never have more than a one module with open ports.

Industrial Networks

Industrial plants use fiber for it's ruggedness, distance and noise immunity. In an industrial environment, electromagnetic interference (EMI) is often a big problem. Motors, relays, welders and other industrial equipment generate a tremendous amount of electrical noise that can cause major problems with copper cabling, especially unshielded cable like UTP. In order to run copper cable in an industrial environment, it is often necessary to pull it through conduit to provide adequate shielding. Fiber is also very flexible, so many industrial robots use fiber for controls, often plastic fiber.

Fiber optics has complete immunity to EMI. You only need to choose a cable type that is rugged enough for the installation, with breakout cable being a good choice for it's heavy-duty construction. The fiber optic cable can be installed easily from point to point, passing right next to major sources of EMI with no effect. Conversion from copper networks is easy with media converters, gadgets that convert most types of systems to fiber optics. Even with the cost of the media converters, the fiber optic network will be less than copper run in conduit.

Industrial plants use fiber for it's ruggedness, distance and noise immunity. In an industrial environment, electromagnetic interference (EMI) is often a big problem. Motors, relays, welders and other industrial equipment generate a tremendous amount of electrical noise that can cause major problems with copper cabling, especially unshielded cable like UTP. In order to run copper cable in an industrial environment, it is often necessary to pull it through conduit to provide adequate shielding. Fiber is also very flexible, so many industrial robots use fiber for controls, often plastic fiber.

Fiber optics has complete immunity to EMI. You only need to choose a cable type that is rugged enough for the installation, with breakout cable being a good choice for it's heavy-duty construction. The fiber optic cable can be installed easily from point to point, passing right next to major sources of EMI with no effect. Conversion from copper networks is easy with media converters, gadgets that convert most types of systems to fiber optics. Even with the cost of the media converters, the fiber optic network will be less than copper run in conduit.

- Military and Platforms

- The military uses fiber everywhere, on bases, platforms (ships and planes), and on the battlefield because it's hard to damage, tap or jam. Airplanes use fiber for its reliability and noise immunity, but also like the lighter weight of fiber. Even millions of cars have fiber networks connecting all the electronics because fiber is immune to noise and saves weight.

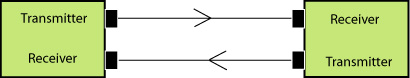

Fiber Optic Links

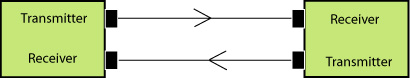

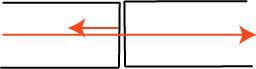

Fiber

optic links work by sending optical signals over fiber. Fiber optic

transmission systems all use data links that work similar to the

diagram shown above. Each fiber link consists of a transmitter on one

end of a fiber and a receiver on the other end. Most systems operate by

transmitting in one direction on one fiber and in the reverse direction

on another fiber for full duplex operation. Transmitters are

semiconductor LEDs or lasers and receivers are semiconductor

photodetectors.

Fiber

optic links work by sending optical signals over fiber. Fiber optic

transmission systems all use data links that work similar to the

diagram shown above. Each fiber link consists of a transmitter on one

end of a fiber and a receiver on the other end. Most systems operate by

transmitting in one direction on one fiber and in the reverse direction

on another fiber for full duplex operation. Transmitters are

semiconductor LEDs or lasers and receivers are semiconductor

photodetectors. For more information on fiber optic links, see the next section on Transmission Systems.

Designing Fiber Optic Networks

This

is a big topic so we have a complete section

on the subject of Design.

Fiber's extra bandwidth and distance capability makes it possible to do things

not possible with copper wire or wireless.

First and foremost, it's necessary to understand thoroughly what

signals are to

be transmitted over the fiber and the specifications of the

transmission equipment. Then map and visit the work site to understand

where the fiber optic cable plant needs to be installed. Know

the standards but use common sense in designing the

installation. Consider what are the possible problems and work around or

prevent them. Don't cut corners which may affect performance or

reliability. Document everything completely. Plan for future expansion

and restoration in case of problems. There is no substitute for

experience and common sense here!

OSP Fiber Optic Transmission Systems

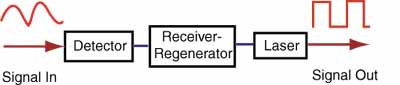

Fiber Optic Datalink

Fiber Optic Datalink

Fiber optic transmission systems all use data links that work similar to the diagram shown above. Each fiber link consists of a transmitter on one end of a fiber and a receiver on the other end. Most systems operate by transmitting in one direction on one fiber and in the reverse direction on another fiber for full duplex operation. It's possible to transmit both directions on one fiber but it requires couplers to do so and fiber is less expensive than couplers. A FTTH passive optical network (PON) is one of the only systems using bidirectional transmission over a single fiber because its network architecture is based around couplers already.

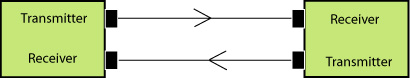

Fiber Optic Transceiver

Most systems use a "transceiver" which includes both transmission and receiver in a single module. The transmitter takes an electrical input and converts it to an optical output from a laser diode or LED. The light from the transmitter is coupled into the fiber with a connector and is transmitted through the fiber optic cable plant. The light from the end of the fiber is coupled to a receiver where a detector converts the light into an electrical signal which is then conditioned properly for use by the receiving equipment.

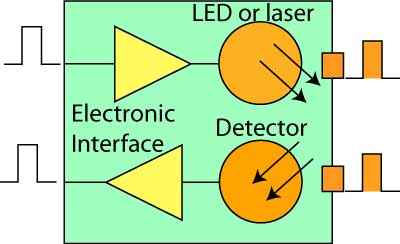

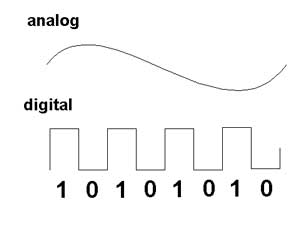

Analog or Digital

Analog

signals are continuously variable signals where the information in the

signal is contained in the amplitude of the signal over time. Digital

signals are sampled at regular time intervals and the amplitude

converted to digital bytes so the information is a digital number.

Analog signals are the natural form of most data, but are subject to

degradation by noise in the transmission system. As an analog signal is

attenuated in a cable, the signal to noise ratio becomes worse so the

quality of the signal degrades. Digital signals can be transmitted long

distances without degradation as the signal is less sensitive to noise.

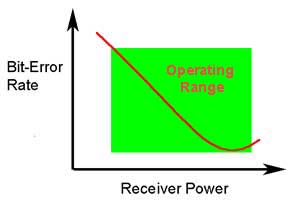

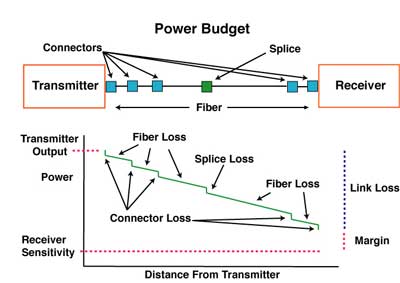

Fiber optic datalinks can be either analog or digital in nature, although most are digital. Both have

some common critical parameters and some major differences. For

both, the optical loss margin or power budget is most important. This is determined

by connecting the link up with an adjustable attenuator in the

cable plant and varying the loss between transmitter and receiver until one can generate the curve

shown above. Analog datalinks will be tested for signal to noise

ratio to determine link margin, while digital links use bit error

rate as a measure of performance. Both links require testing over

the full bandwidth specified for operation, but most data links

are now specified for a specific network application, like AM

CATV or RGB color monitors for analog links and SONET, Ethernet or Fibre Channel for digital links.

The

sources used for fiber optic transmitters need to meet several

criteria: it has to be at the correct wavelength, be able to be

modulated fast enough to transmit data and be efficiently coupled into

fiber.

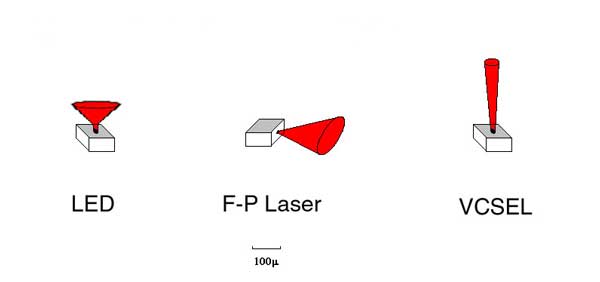

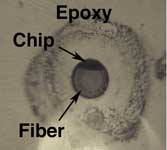

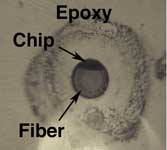

Four types of sources are commonly

used, LEDs, fabry-perot (FP) lasers, distributed feedback (DFB) lasers and vertical cavity surface-emitting

lasers (VCSELs). All convert electrical signals into optical

signals, but are otherwise quite different devices. All three are tiny

semiconductor devices (chips). LEDs and VCSELs are fabricated on

semiconductor wafers such that they emit light from the surface of the

chip, while f-p lasers emit from the side of the chip from a laser

cavity created in the middle of the chip.

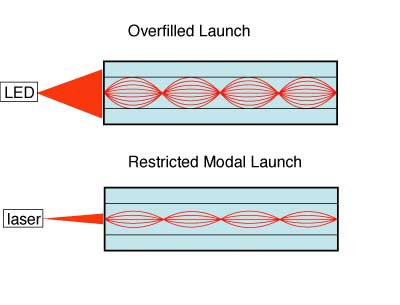

LEDs

have much lower power outputs than lasers and their

larger, diverging light output pattern makes them harder to couple

into fibers, limiting them to use with multimode fibers. Laser have

smaller tighter light outputs and are easily coupled to singlemode

fibers, making them ideal for long distance high speed links. LEDs have

much less bandwidth than lasers and are limited to systems operating up

to about 250 MHz or around 200 Mb/s. Lasers have very high bandwidth

capability, most being useful to well over 10 GHz or 10 Gb/s.

Because of their fabrication methods, LEDs and VCSELs are cheap to make. Lasers are more expensive because creating the laser cavity inside the device is more difficult, the chip must be separated from the semiconductor wafer and each end coated before the laser can even be tested to see if its good.Typical Fiber Optic Source Specifications

Because of their fabrication methods, LEDs and VCSELs are cheap to make. Lasers are more expensive because creating the laser cavity inside the device is more difficult, the chip must be separated from the semiconductor wafer and each end coated before the laser can even be tested to see if its good.Typical Fiber Optic Source Specifications

| Device Type | Wavelength (nm) | Power into Fiber (dBm) | Bandwidth | Fiber Types |

| LED | 850, 1300 | -30 to -10 | <250 MHz | MM |

| Fabry-Perot Laser | 850, 1310 (1280-1330) 1550 (1480-1650) | 0 to +10 | >10 GHz | MM, SM |

| DFB Laser | 1550 (1480-1650) | 0 to +25 | >10 GHz | SM |

| VCSEL | 850 | -10 to 0 | >10 GHz | MM |

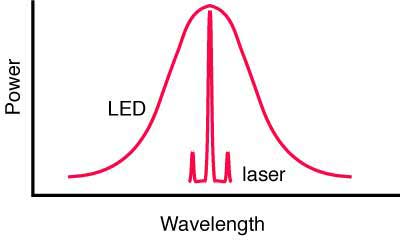

LEDs

have a limited bandwidth while all types of lasers are very fast.

Another big difference between LEDs and both types of lasers is the

spectral output. LEDs have a very broad spectral output which causes

them to suffer chromatic dispersion in fiber, while lasers have a

narrow spectral output that suffers very little chromatic dispersion. DFB lasers, which are used in long distance and DWDM systems, have the narrowest spectral width which minimizes chromatic dispersion on the longest links. DFB lasers are also

highly linear (that is the light output directly follows the electrical

input) so they can be used as sources in AM CATV systems.

The choice of these devices is determined mainly by speed and fiber compatibility issues. As many premises systems using multimode fiber have exceeded bit rates of 1 Gb/s, lasers (mostly VCSELs) have replaced LEDs. The output of the LED is very broad but lasers are very focused, and the sources will have very different modal fill in the fibers. The restricted launch of the VCSEL (or any laser) makes the effective bandwidth of the fiber higher, but laser-optimized fiber, usually OM3, is the choice for lasers.

The

electronics for a transmitter are simple. They convert an incoming

pulse (voltage) into a precise current pulse to drive the source.

Lasers generally are biased with a low DC current and modulated above

that bias current to maximize speed.

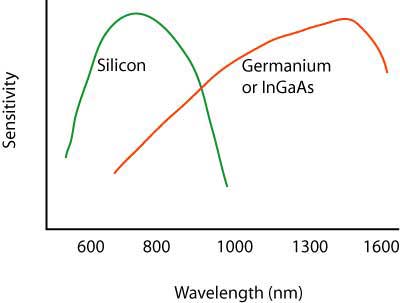

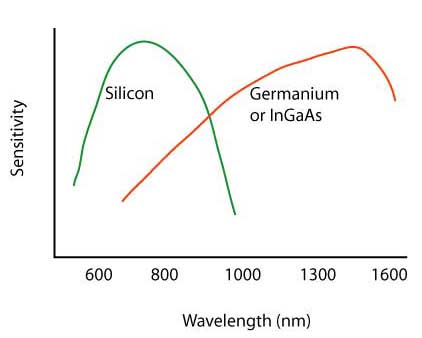

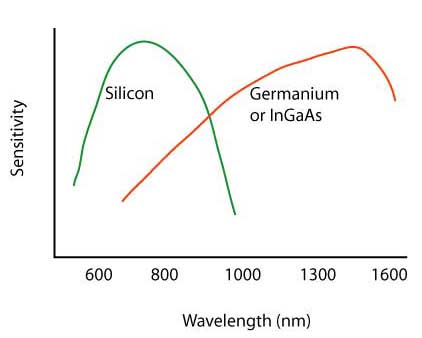

Receivers

use semiconductor detectors (photodiodes or photodetectors) to convert

optical signals to electrical signals. Silicon photodiodes

are used for short wavelength links (650 for POF and 850 for glass MM

fiber). Long wavelength systems usually use InGaAs (indium gallium

arsenide) detectors as they have lower noise than germanium which

allows for more sensitive receivers.

Very high speed systems sometimes use avalanche photodiodes (APDs) that are biased at high voltage to create gain in the photodiode. These devices are more expensive and more complicated to use but offer significant gains in performance.

Packaging

Transcivers

are usually packaged in industry standard packages like these XFP

modules for gigabit datalinks(L) and Xenpak (R). The XFP modules

connect to a duplex LC connector on the optical end and a standard

electrical interface on the other end. The Xenpak are for 10 gigabit

networks but use SC duplex connection. Both are similar to media converters but are powered from the equipment they are built into.

Performance

Just

as with copper

wire or radio transmission, the performance of the fiber optic

data link can be determined by how well the reconverted electrical

signal out of the receiver matches the input to the transmitter.

The discussion of performance on datalinks applies directly to

transceivers which supply the optical to electrical conversion.

Every

manufacturer of transcivers specifies

their product for receiver sensitivity (perhaps a minimum power

required)

and minimum power coupled into the fiber from the source. Those

specifications will end up being the datalink specifications on the

final product used in the field.

Why Is WDM Used?

With the exponential growth in communications, caused mainly by the wide acceptance of the Internet, many carriers are finding that their estimates of fiber needs have been highly underestimated. Although most cables included many spare fibers when installed, this growth has used many of them and new capacity is needed. Three methods exist for expanding capacity: 1) installing more cables, 2) increasing system bitrate to multiplex more signals or 3) wavelength division multiplexing.

Installing more cables will be the preferred method in many cases, especially in metropolitan areas, since fiber has become incredibly inexpensive and installation methods more efficient (like mass fusion splicing.) But if conduit space is not available or major construction is necessary, this may not be the most cost effective.

Increasing system bitrate may not prove cost effective either. Many systems are already running at SONET OC-48 rates (2.5 GB/s) and upgrading to OC-192 (10 GB/s) is expensive, requires changing out all the electronics in a network, and adds 4 times the capacity, more than may be necessary.

The third alternative, wavelength division multiplexing (WDM), has proven more cost effective in many instances. It allows using current electronics and current fibers, but simply shares fibers by transmitting different channels at different wavelengths (colors) of light. Systems that already use fiber optic amplifiers as repeaters also do not require upgrading for most WDM systems.

With the exponential growth in communications, caused mainly by the wide acceptance of the Internet, many carriers are finding that their estimates of fiber needs have been highly underestimated. Although most cables included many spare fibers when installed, this growth has used many of them and new capacity is needed. Three methods exist for expanding capacity: 1) installing more cables, 2) increasing system bitrate to multiplex more signals or 3) wavelength division multiplexing.

Installing more cables will be the preferred method in many cases, especially in metropolitan areas, since fiber has become incredibly inexpensive and installation methods more efficient (like mass fusion splicing.) But if conduit space is not available or major construction is necessary, this may not be the most cost effective.

Increasing system bitrate may not prove cost effective either. Many systems are already running at SONET OC-48 rates (2.5 GB/s) and upgrading to OC-192 (10 GB/s) is expensive, requires changing out all the electronics in a network, and adds 4 times the capacity, more than may be necessary.

The third alternative, wavelength division multiplexing (WDM), has proven more cost effective in many instances. It allows using current electronics and current fibers, but simply shares fibers by transmitting different channels at different wavelengths (colors) of light. Systems that already use fiber optic amplifiers as repeaters also do not require upgrading for most WDM systems.

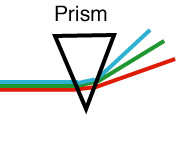

How Does WDM Work?

It is easy to understand WDM. Consider the fact that you can see many different colors of light - reg, green, yellow, blue, etc. all at once. The colors are transmitted through the air together and may mix, but they can be easily separated using a simple device like a prism, just like we separate the "white" light from the sun into a spectrum of colors with the prism.

It is easy to understand WDM. Consider the fact that you can see many different colors of light - reg, green, yellow, blue, etc. all at once. The colors are transmitted through the air together and may mix, but they can be easily separated using a simple device like a prism, just like we separate the "white" light from the sun into a spectrum of colors with the prism.

Separating a beam of

light into

its colors

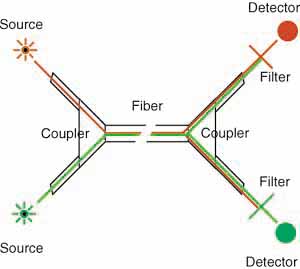

This technique was first

demonstrated with

optical fiber in the early 80s when telco fiber optic links still

used multimode fiber. Light at 850 nm and 1300 nm was injected

into the fiber at one end using a simple fused coupler. At the

far end of the fiber, another coupler split the light into two

fibers, one sent to a silicon detector more sensitive to 850 nm

and one to a germanium or InGaAs detector more sensitive to 1300

nm. Filters removed the unwanted wavelengths, so each detector

then was able to receive only the signal intended for it.

WDM with couplers

and filters

By the late 80s, all telecom

links were

singlemode fiber, and coupler manufactures learned how to make

fused couplers that could separate 1300nm and 1550 nm signals

adequately to allow WDM with simple, inexpensive components. However,

these had limited usefulness, as fiber was designed differently

for 1300nm and 1550 nm, due to the dispersion characteristics

of glass. Fiber optimized at 1300 nm was used for local loop links,

while long haul and submarine cables used dispersion-shifted fiber

optimized for performance at 1550 nm. This simple version of WDM is

widely used in fiber to the home (FTTH) applications. Signals are sent

downstream to the subscriber at 1490 nm (and 1550 for analog CATV if

used) and upstream at 1310 n.

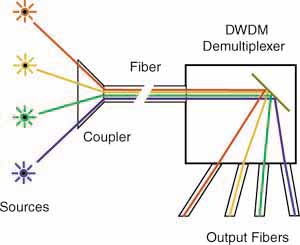

With the advent of fiber optic amplifiers for repeaters in the late 80s (see below), emphasis shifted to the 1550 nm transmission band. WDM only made sense if the multiplexed wavelengths were in the region of the fiber amplifiers operating range of 1520 to 1560 nm. It was not long before WDM equipment was able to put 4 signals into this band, with wavelengths about 10 nm apart.

The input end of a WDM system is really quite simple. It is a simple coupler that combines all the inputs into one output fiber. These have been available for many years, offering 2, 4, 8, 16, 32 or even 64 inputs. It is the demultiplexer that is the difficult component to make.

With the advent of fiber optic amplifiers for repeaters in the late 80s (see below), emphasis shifted to the 1550 nm transmission band. WDM only made sense if the multiplexed wavelengths were in the region of the fiber amplifiers operating range of 1520 to 1560 nm. It was not long before WDM equipment was able to put 4 signals into this band, with wavelengths about 10 nm apart.

The input end of a WDM system is really quite simple. It is a simple coupler that combines all the inputs into one output fiber. These have been available for many years, offering 2, 4, 8, 16, 32 or even 64 inputs. It is the demultiplexer that is the difficult component to make.

WDM demultiplexer

The demultiplexer takes the

input fiber

and collimates the light into a narrow, parallel beam of light.

It shines on a grating (a mirror like device that works like a

prism, similar to the data side of a CD) which separates the light

into the different wavelengths by sending them off at different

angles. Optics capture each wavelength and focuses it into a fiber,

creating separate outputs for each separate wavelength of light.

DWDM

Current systems offer from 4 to 32 channels of wavelengths. The higher numbers of wavelengths has lead to the name Dense Wavelength Division Multiplexing or DWDM. The technical requirement is only that the lasers be of very specific wavelengths and the wavelengths are very stable, and the DWDM demultiplexers capable of distinguishing each wavelength without crosstalk.

Current systems offer from 4 to 32 channels of wavelengths. The higher numbers of wavelengths has lead to the name Dense Wavelength Division Multiplexing or DWDM. The technical requirement is only that the lasers be of very specific wavelengths and the wavelengths are very stable, and the DWDM demultiplexers capable of distinguishing each wavelength without crosstalk.

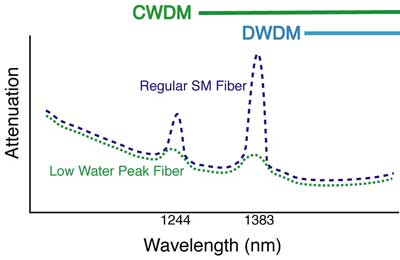

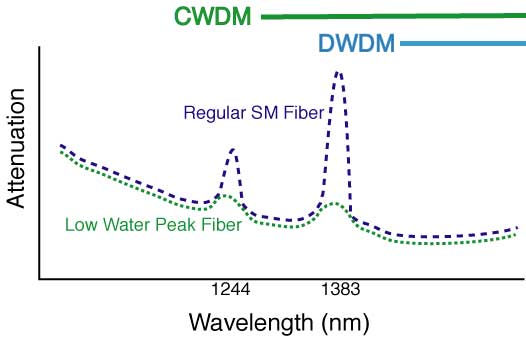

CWDM

Coarse wavelength-division multiplexing is another variant of WDM. Generally CWDM refers to using lasers spaced 20 nm apart over the full range of 1260 to 1670 nm. It only works on low water peak fibers, where the high water absorption bands have been eliminated in the manufacture of the fiber.

Coarse wavelength-division multiplexing is another variant of WDM. Generally CWDM refers to using lasers spaced 20 nm apart over the full range of 1260 to 1670 nm. It only works on low water peak fibers, where the high water absorption bands have been eliminated in the manufacture of the fiber.

Advantages of WDM

A WDM system has some features that make them very useable. Each wavelength can be from a normal link, for example a OC-48 link, so you do not obsolete most of your current equipment. You merely need laser transmitterss chosen for wavelengths that match the WDM demultiplexer to make sure each channel is properly decoded at the receiving end.

If you use an OC-48 SONET input, you can have 4X2.5 GB/s = 10 GB/s up to 32 X 2.5 GB/s = 80 GB/s. While 32 channels are the maximum today, future enhancements are expected to offer 80-128 channels!

And you are not limited to SONET, you can use Gigabit Ethernet for example, or you can mix and match SONET and Gigabit Ethernet or any other digital signals! You can even mix in analog channels like CATV, as is done with BPON FTTH systems.

A WDM system has some features that make them very useable. Each wavelength can be from a normal link, for example a OC-48 link, so you do not obsolete most of your current equipment. You merely need laser transmitterss chosen for wavelengths that match the WDM demultiplexer to make sure each channel is properly decoded at the receiving end.

If you use an OC-48 SONET input, you can have 4X2.5 GB/s = 10 GB/s up to 32 X 2.5 GB/s = 80 GB/s. While 32 channels are the maximum today, future enhancements are expected to offer 80-128 channels!

And you are not limited to SONET, you can use Gigabit Ethernet for example, or you can mix and match SONET and Gigabit Ethernet or any other digital signals! You can even mix in analog channels like CATV, as is done with BPON FTTH systems.

Repeaters

Another technology that facilitates DWDM is the development of fiber optic amplifiers for use as repeaters. They can amplify numerous wavelengths of light simultaneously, as long as all are in the wavelength range of the FO amplifier. They work best in the range of 1520-1560 nm, so most DWDM systems are designed for that range. Now that fiber has been made with less effect from the OH absorption bands at 1400 nm and 1600 nm, the possible range of DWDM has broadened considerably. Technology needs development for wider range fiber amplifiers to take advantage of the new fibers.

Another technology that facilitates DWDM is the development of fiber optic amplifiers for use as repeaters. They can amplify numerous wavelengths of light simultaneously, as long as all are in the wavelength range of the FO amplifier. They work best in the range of 1520-1560 nm, so most DWDM systems are designed for that range. Now that fiber has been made with less effect from the OH absorption bands at 1400 nm and 1600 nm, the possible range of DWDM has broadened considerably. Technology needs development for wider range fiber amplifiers to take advantage of the new fibers.

Fiber

Amplifiers

While the low loss of optical

fiber allows

signals to travel hundreds of kilometers, extremely long haul

lines and submarine cables require regenerators or repeaters to

amplify the signal periodically. In the beginning, repeaters basically

consisted of a receiver followed by a transmitter. The incoming

signal was converted from a light signal to an electrical signal

by a receiver, cleaned up to remove as much noise as possible,

then was retransmitted by another laser transmitter.

Electronic Repeater

These repeaters added noise to

the signal,

consumed much power and were complicated, which means they were

a source of failure. They also had to be made for the specific

bit rate of transmission and upgrading required replacing all

the repeaters, a really difficult task in an undersea cable!

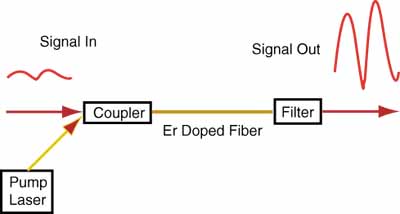

Since the 1960s, researchers knew how to make fiber lasers. Proper doping of the fiber (introducing small amounts of active elements into the glass fiber) allowed it to be pumped with external light sources until stimulated emission occurred. While making fiber amplifiers was hypothesized early in the stages of fiber optic development, it was not until 1987 that working models were realized. Major contributors to the development included Bell Labs and NTT.

The typical fiber amplifier works in the 1550 nm band and consists of a length of fiber doped with Erbium pumped with a laser at 980. The pump laser supplies the energy for the amplifier, while the incoming signal stimulates emission as the pulse passes through the doped fiber. The stimulated emission stimulates more emission, so there is a rapid, exponential growth of photons in the doped fiber. Gains of >40 dB (10,000X) are possible with power outputs >+20 dBm (100 mW).

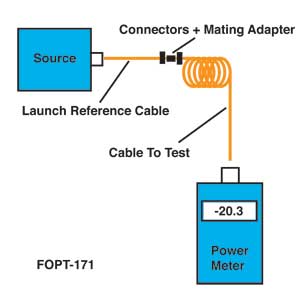

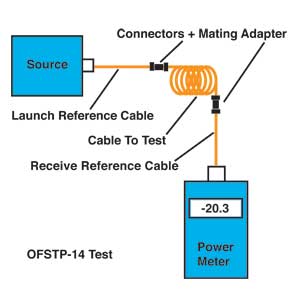

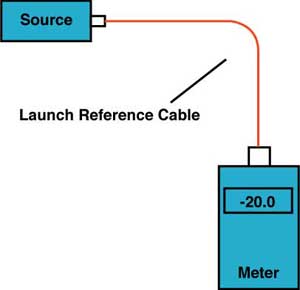

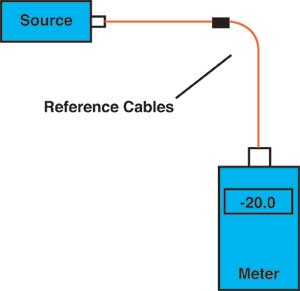

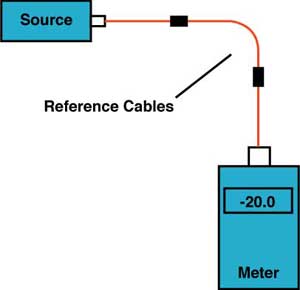

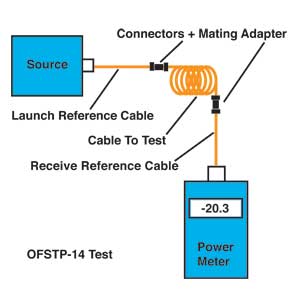

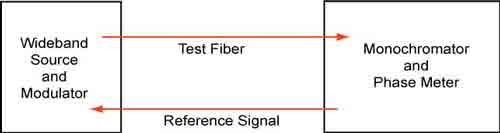

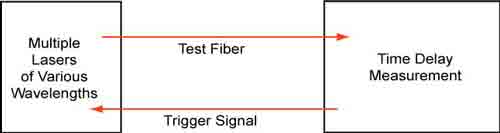

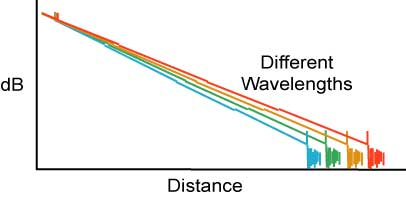

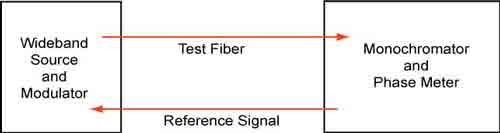

Since the 1960s, researchers knew how to make fiber lasers. Proper doping of the fiber (introducing small amounts of active elements into the glass fiber) allowed it to be pumped with external light sources until stimulated emission occurred. While making fiber amplifiers was hypothesized early in the stages of fiber optic development, it was not until 1987 that working models were realized. Major contributors to the development included Bell Labs and NTT.